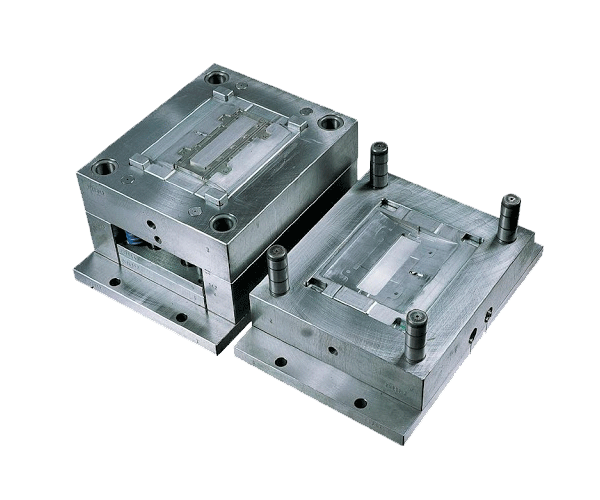

Plastic Moulds

Plastic molds, also known as injection molds or plastic injection molds, are tools used in the manufacturing of plastic parts through the injection molding process. These molds are typically made from steel or aluminum and are precision-machined to create the desired shape and features of the plastic part.

-

Design: The first step in creating a plastic mold is designing the part to be manufactured. This can be done using computer-aided design (CAD) software.

-

Mold Creation: Once the design is finalized, the mold is created using CNC machining or other precision manufacturing techniques. The mold is typically made in two halves, called the core and cavity, which fit together to form the complete mold.

-

Injection Molding: The mold is mounted onto an injection molding machine. Plastic pellets are heated to a molten state and injected under high pressure into the mold cavity. The plastic quickly cools and solidifies, taking on the shape of the mold.

-

Ejection: After the plastic has cooled and solidified, the mold opens, and the newly formed plastic part is ejected from the mold.

-

Finishing: Depending on the application, the plastic part may require additional finishing processes such as trimming, surface treatment, or assembly.