Silicone Profile Manufacturers

Contact : +91 97404 04503

Silicone Profile Manufacturers: A Comprehensive Overview

Silicone profiles are essential components in various industries due to their versatility, durability, and excellent resistance to extreme temperatures, chemicals, and UV light. These profiles, made from high-quality silicone rubber, are widely used in automotive, aerospace, medical, construction, and consumer goods sectors. This article delves into the role of silicone profile manufacturers, highlighting the importance of choosing the right supplier for your needs.

What Are Silicone Profiles?

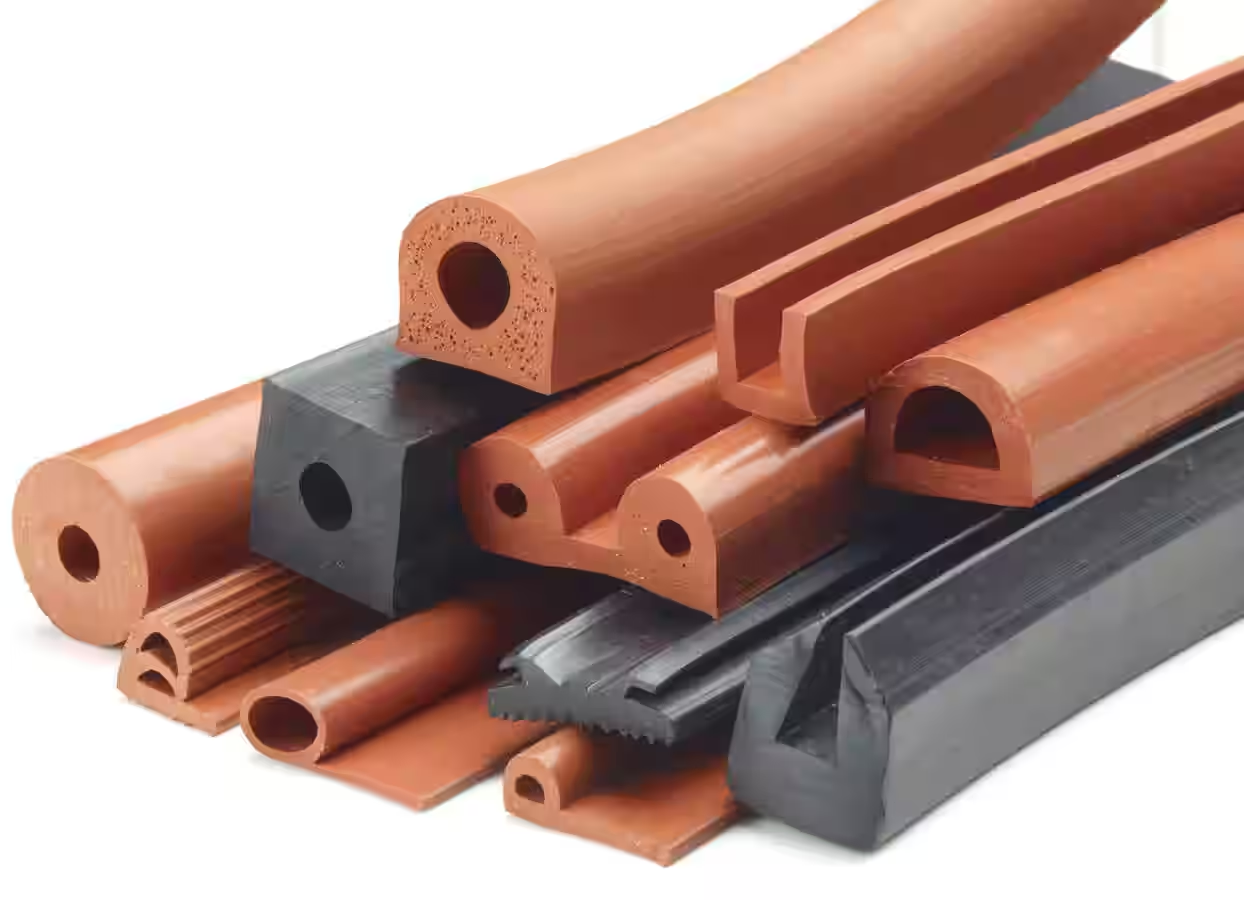

Silicone profiles are extruded shapes made from silicone rubber, designed to meet specific sealing, insulating, and protective requirements. They come in various forms, including gaskets, seals, tubes, and custom shapes, making them suitable for diverse applications. The key characteristics of silicone profiles include flexibility, resilience, and the ability to withstand harsh environmental conditions.

The Manufacturing Process

The manufacturing of silicone profiles involves a precise extrusion process. Silicone rubber is fed into an extruder, where it is heated and forced through a die to create the desired shape. After extrusion, the profiles undergo curing, typically through high-temperature vulcanization, to enhance their physical properties. Some manufacturers also offer post-extrusion processes like cutting, splicing, and joining to create complex and customized profiles.

Importance of Choosing the Right Manufacturer

Selecting the right silicone profile manufacturer is crucial for ensuring the quality and performance of the final product. Here are some factors to consider:

-

Experience and Expertise: Manufacturers with extensive experience in silicone extrusion can provide valuable insights into material selection, design optimization, and cost-effective production methods.

-

Quality Control: Reputable manufacturers adhere to strict quality control standards, ensuring that their products meet industry specifications. They often have certifications such as ISO 9001, which guarantees consistent quality.

-

Customization Capabilities: A good manufacturer should offer the ability to produce custom silicone profiles tailored to your specific requirements. This includes providing a range of hardness levels, colors, and shapes.

-

Material Selection: Leading manufacturers use high-quality silicone rubber, including specialized grades like food-grade silicone, medical-grade silicone, and flame-retardant silicone. This ensures that the profiles are safe and effective for their intended use.

-

Technical Support: A reliable manufacturer provides technical support throughout the project, from the initial design phase to final production. This includes assistance with prototyping, testing, and troubleshooting.

-

Timely Delivery: On-time delivery is critical, especially for industries with tight production schedules. Established manufacturers have efficient production processes and logistics systems to meet deadlines.

Applications of Silicone Profiles

Silicone profiles are used in a wide range of applications due to their exceptional properties:

- Automotive: Used in door seals, window seals, and engine gaskets to provide weatherproofing and vibration damping.

- Aerospace: Essential for sealing and insulating components exposed to extreme temperatures and pressure variations.

- Medical: Used in medical devices and equipment, where biocompatibility and resistance to sterilization processes are crucial.

- Construction: Applied in glazing systems, curtain walls, and weatherproofing applications.

- Consumer Goods: Found in household appliances, cookware, and electronic devices.

Conclusion

Silicone profile manufacturers play a vital role in delivering high-quality components that meet the rigorous demands of various industries. By choosing a manufacturer with the right expertise, quality control, and customization capabilities, you can ensure that your silicone profiles will perform reliably and efficiently in their intended applications. Whether you need standard profiles or custom solutions, partnering with a reputable silicone profile manufacturer is key to achieving optimal results.