All Mold Work Manufacturer

Contact : +91 97404 04503

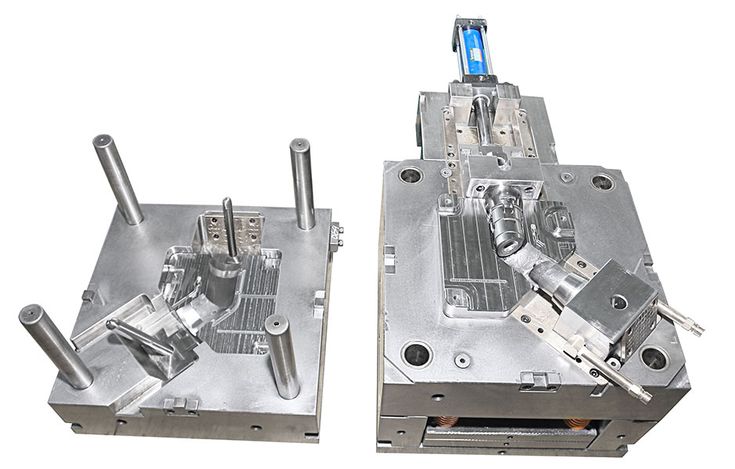

Overview of Mold Work Manufacturers

Mold work manufacturers play a crucial role in the production of various goods across multiple industries, including automotive, aerospace, consumer products, and medical devices. These manufacturers specialize in creating molds that are used to shape and form materials into specific designs, ensuring precision, efficiency, and high-quality output.

Key Roles and Responsibilities

-

Design and Engineering: The first step in mold manufacturing is the design phase. Manufacturers work closely with clients to understand their requirements and translate them into detailed mold designs. This involves selecting the right materials, determining the mold's complexity, and ensuring it meets production specifications. Advanced computer-aided design (CAD) software is often employed to create 3D models of the molds.

-

Material Selection: Choosing the right material for molds is critical to the quality and longevity of the finished products. Common materials include steel, aluminum, and various polymers, each offering different benefits such as durability, thermal conductivity, and cost-effectiveness. Manufacturers assess the intended use of the mold to make the best material selection.

-

Manufacturing Process: Once the design is finalized, manufacturers proceed to the production phase. This typically involves machining processes such as milling, turning, and grinding to shape the mold components accurately. High-precision CNC (Computer Numerical Control) machines are commonly used for this purpose, allowing for high levels of accuracy and repeatability.

-

Assembly and Testing: After the individual components are manufactured, they are assembled to create the final mold. This phase also includes rigorous testing to ensure that the mold performs as expected. Testing can involve checking for dimensional accuracy, surface finish, and functionality under various conditions.

-

Maintenance and Repair: Mold work manufacturers also provide maintenance and repair services to extend the life of the molds. Regular maintenance is essential to prevent wear and tear, which can affect the quality of the products produced. Manufacturers may offer service contracts to their clients to ensure molds remain in optimal condition.

Importance in Various Industries

Mold work manufacturers are essential to various sectors, including:

-

Automotive: In the automotive industry, molds are used to produce components such as dashboards, bumpers, and exterior panels. The precision and quality of these molds directly impact the performance and safety of vehicles.

-

Aerospace: Molds used in aerospace must meet stringent safety and performance standards. Manufacturers create molds for complex components like fuselage sections and engine parts, where precision is vital.

-

Consumer Products: From packaging to household items, molds are used to create a wide array of consumer products. The design and functionality of these molds influence the product's marketability and user experience.

-

Medical Devices: In the medical field, molds are used to manufacture devices such as syringes, surgical tools, and diagnostic equipment. The reliability and sterility of these molds are critical to patient safety.

Conclusion

In summary, mold work manufacturers are integral to the production processes across many industries. Their expertise in design, material selection, manufacturing, and maintenance ensures that molds are produced with high precision and quality. As industries continue to evolve and demand more innovative products, the role of mold work manufacturers will remain vital in facilitating these advancements.